This studio course is a practice and prototyping study of transdisciplinary, collaborative design processes to address real-world problems in sociotechnical innovation provided by clients from industry, business, government, and nonprofit organizations. Students from participating majors in the program take this class in the Fall semester of their Junior year. Student teams engage in defining and analyzing real-world problems using Systems thinking and the Collaboration Sociotechnical Innovation Model (CSIM) Four Set framework. Other activities in this class includes (but not excludes): Identification and analysis of stakeholders. Skills discovery and transdisciplinary team building. Rapid Prototyping. Collaborative innovation. Evidence-based decision-making. Iterative Design. Troubleshooting.

Studio Structure

This studio class uses a distributed model of instruction. Each team work directly with a faculty mentor. During Fall 2021 I advised a team working on developing a digital-physical system to monitor the psychological state of workers while performing the complex task of composite ply lay-up. We began by doing a comprehensive and fast-paced literature review which lead to finding the gap in the knowledge about the effect of strenuous tasks on the cognitive load experienced by the workers.

Versatility & Agility

A key pedagogical goal of this studio is to help students become versatile and agile. Pace of project development in this class is faster than previous studio classes in the program and requires high levels of commitment, collaboration, and engagement. Students work with various external partners to gain insight about real-world problems that they are focusing on.

System Prototyping

Production systems in general and those of the aviation industry are complex in nature. To help students better understand the scope of these systems to find gaps that they can address with their innovative approaches in collaboration with Gregory Garrett (Boeing) we developed a methodology to provide meaningful abstractions of these systems. The students in my team began with a general production task and gradually were introduced to various tasks performed in the manufacturing floor's workcells until they found composite ply lay-up process as the task to focus on.

Using Unity game engine the students developed simulations for the task and developed an abstracted low-fidelity physical representation of the task using wood glue and sheets of plastic as proxies for flexible and sticky composite ply. Their Unity simulation represented the composite ply lay-up with a higher level of fidelity as they used a particle-based physics engine to simulate cloth-like virtual assets (Obi Cloth). The team's final prototype effectively presented the complexities of the task that the EEG device (Open BCI) was able to capture. Please refer to the project page (available at this link) for more information about this project.

Peer-Review and Critique

The peer-review for this studio happened synchronously and after milestone presentations. Students had the opportunity to attend the presentations and provide feedback to peers. External partners were present during the presentations as well which afforded the presenting teams a rich environment to gain insight about their project directions.

Presentations

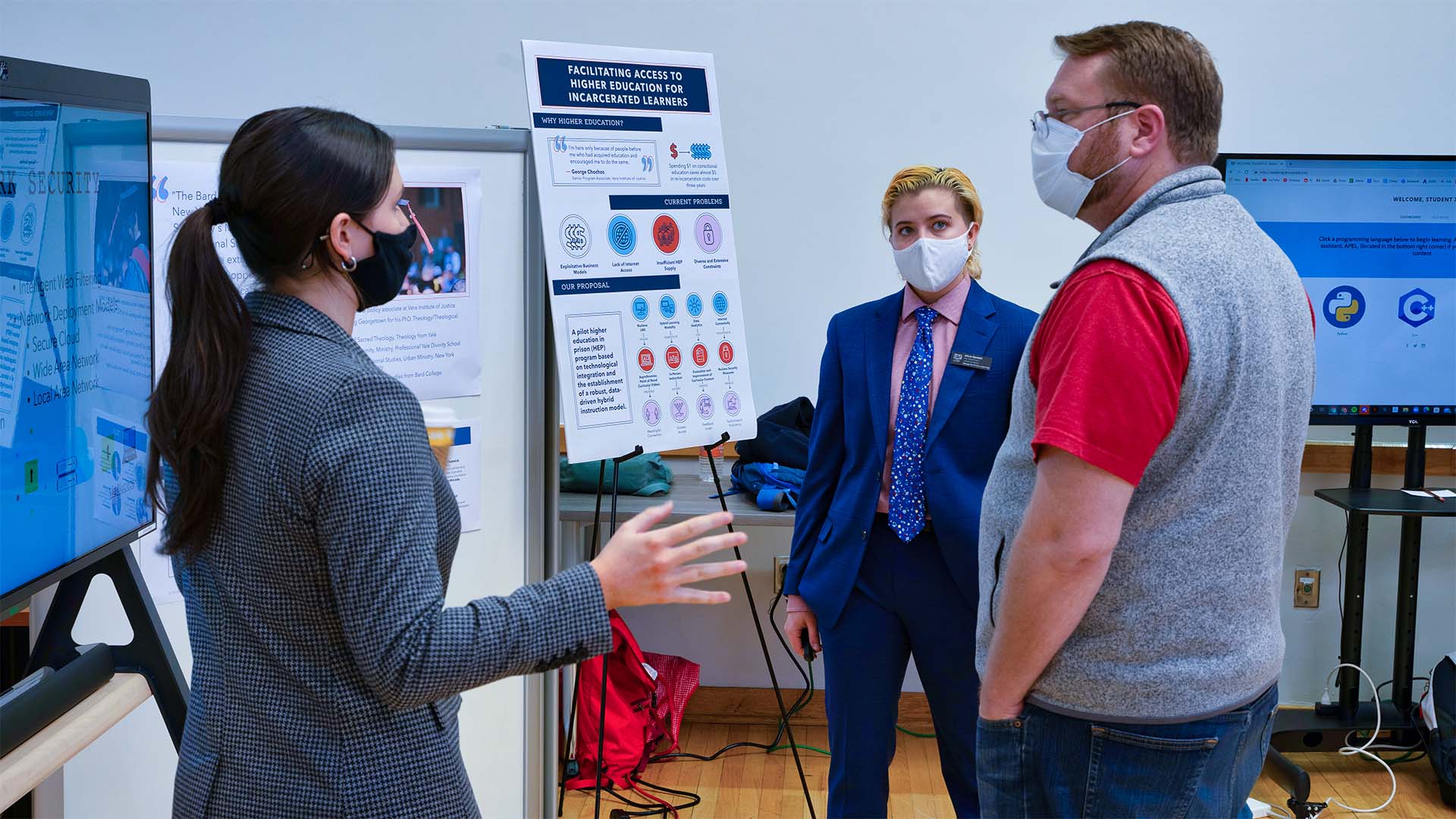

We held a showcase for all the students in the Junior Design Studio and Transdisciplinary Fusion Studio I in Fall 2021. The following set of images are from my team working on EEG Monitoring of Composite Ply Lay-up.

The following set of images present the work of other teams taking the junior design studio working with other faculty mentors.

In Media

Calhoun Honors Discovery Showcase

Publications

"Virginia Tech and Boeing University-Industry Collaboration; use of a 4-Tier Sociotechnical Approach to Reduce Ergonomics Related Hazards." Shahabedin Sagheb, Gregory Garrett, and Robert Smith. Institute of Industrial and Systems Engineers Annual Conference & Expo (IISE 2022)Annual Conference. Proceedings: 1-6, 2022.

"Project-based development as a model for transdisciplinary research and education."Shahabedin Sagheb, Katie Walkup, and Robert Smith. Journal of Systemics, Cybernetics and Informatics 20.5 (2022): 17-32.

“Project-based Learning Using the Collaborative Sociotechnical Innovation Model” Shahabedin Sagheb, Amy Arnold, Robert Smith. In 14th Annual Conference on Higher Education Pedagogy).

"Coalitional Curricular Design: Industry-Academic Co-creation of Technical Communication Modules." Katie Walkup, Shahabedin Sagheb, and Robert Smith. In Proceedings of the 40th ACM International Conference on Design of Communication, pp. 140-142. 2022.